Foiling for Print

Have you ever wondered how some business cards, flyers and product packaging boxes feature metallic, shiny logos and text? That’s foil stamping, also known as foiling a subtle but beautiful way to enhance printed designs.

At Document Corners, foiling can be added to your print run via digital foiling or hot foil stamping – but what’s the difference? Here’s a quick guide to both methods and which one offers the best option for your print requirements…

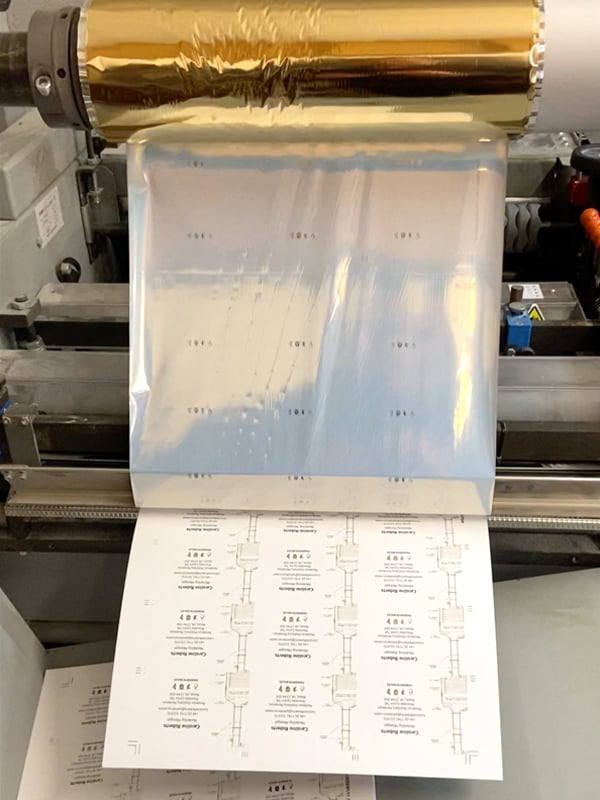

Digital Foiling

If you’re looking for a faster turnaround and/or a lower price tag, digital foiling is the way to go. This method simply requires a digital artwork file, which tells the digital foil machine where to ‘print’ the foil onto the paper.

The pros of digital foiling:

More design flexibility. Digital foiling offers more design freedom as it can produce intricate designs, gradients, and fine lines that can be difficult to achieve with traditional hot foil stamping.

No need for additional equipment. Digital foiling can be done with a regular digital printer, while hot foil stamping requires special equipment and a skilled operator to set up the machine and stamp the foil onto the paper.

Lower cost for multi-color foiling. Digital foiling can produce multi-color foiling in a single pass, which can be more cost-effective than using multiple foil dies for traditional hot foil stamping.

The cons of digital foiling:

A disadvantage of digital foiling is that it may not be suitable for all types of paper or card stock. Some materials may not hold the foil well, resulting in a less crisp and defined finish. Additionally, the range of available foil colors may be more limited compared to hot foil stamping. Finally, digital foiling may not be as durable as hot foil stamping, as it is more prone to wear and tear over time.

Digital foiling at Better Printing

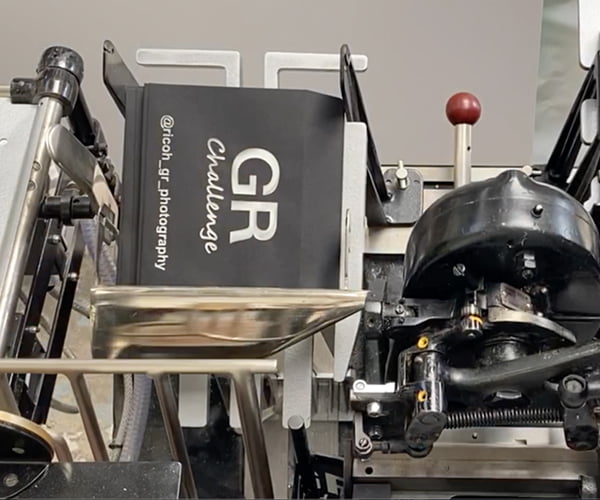

Hot foil stamping

Hot foil stamping is the most expensive option due to the unique custom-made die that needs to be created for each design. The cost of the die will depend on the size and complexity of the design, so it’s important to factor in this extra cost when considering hot foil stamping. However, the results are stunning and offer a level of luxury and sophistication that can’t be achieved with digital foiling. Hot foil stamping can also be done on a wider variety of materials, including leather, plastic, and wood.

Custom brass die block for foiling

Coloured hot stamping foils

The pros of hot foil stamping:

Hot foil stamping becomes more economical for longer print runs since the cost of creating the custom-made die plate is spread out over a larger number of items. So if you’re looking to produce a larger quantity of items with foil stamping, it may end up being the more cost-effective option in the long run.

The cons of hot foil stamping:

If you’re looking to add a touch of elegance to your document corners, you can opt for hot foil stamping or digital foiling. Hot foil stamping can create finer details and subtly enhance the shimmer of the foiled elements with a slightly de-bossed effect. However, it comes with additional costs for the assembly of the foiling die and is more economical for longer print runs. On the other hand, digital foiling is more cost-effective for short print runs and has quicker production times, making it ideal for urgent orders. Better Printing offers both hot foil stamping and digital foiling in-house from our Southampton print factory, ensuring no extra outsourcing costs. So, whether you want to add a touch of luxury to your document corners or create a stunning design, we’ve got you covered.

Hot foil stamping machine

If you have any additional questions about any type of foiling then call us on 023 8087 8037 or email us.